| Grade | 201/202/301/303/304/304L/316/316L/321/309S/310S/401/409/410/420J1/420J2/430/439/443/444/630/631/904L/2205/2507/2520 etc |

| Surface Finish | 2B, BA, NO.1, NO.4, 8K, HL, Embossing, Satin, Mirror, ect |

| Standard | JIS/SUS/GB/DIN/ASTM/AISI/EN |

| Technique | Cold Rolled; Hot Rolled |

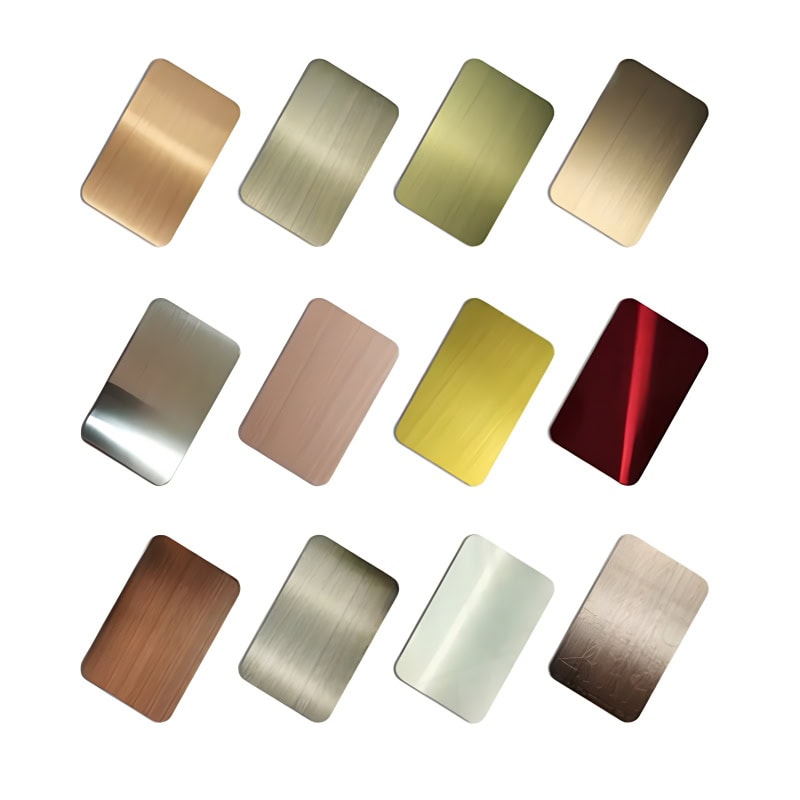

| Color | Golden, Black , Sapphire Blue, Brown, Rose gold, Bronze, Purple, Gray, Silver, Champagne, Violet, Blue Diamond, etc |

| Width | 1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm |

| Length | 2000mm, 2438mm, 2500mm, 3000mm, 6000mm or as required |

| Application | Architecture, Furniture Industry, Decoration Industry, Automobile Field, Arts and Crafts, Mechanical Manufacturing etc. |

Product Features

Rich Color:

The mature technology of coloring gives the performance of rich colors, which can meet personalized color needs with abundant colors, from classic three colors, black, white and gray to bright red, yellow, blue and other colors, high – end champagne and rose gold can also suitable for different design styles.

Superb Corrosion Resistance:

Stainless steel after special treatment has a dense oxide film on the surface, strong acid and alkali corrosion resistance, moisture resistance, extending service life.

Tight Strength and Stability:

Integrates high-strength stainless steel and optimized processes, making it capable of withstanding a great deal of pressure and impact without deforming or damaging itself.

Hassle-Free Cleaning and Maintenance:

Smooth surfaces do not attract dirt or dust. That means you can just wipe to make them look – new regularly and you will not have to clean up as much.

Applications

Exterior wall decoration:

rich in color, good weather resistance, can be paved over a large area or partially embellished to enhance the aesthetics and artistic sense of the building and protect the main body of the building.

Indoor walls and partitions:

create characteristic background walls, realize space division, add personality and sense of hierarchy, and create a transparent and creative indoor layout.

Cabinet door panels:

durable and easy to clean, matching with various decoration styles, resisting kitchen fumes and vapors, keeping neat and beautiful.

Furniture panels:

used for TV cabinets, coffee tables and other panels, unique texture and visual effect, to meet the needs of daily use.

Elevator car:

Enhance the aesthetics, resist scratches and stains, and provide a comfortable riding experience.

Installation Methods

Surface Preparation:

Ensure the installation surface is smooth, clean, dry, free of oil and dust. Level uneven areas and clean as needed.

Mechanical Fixing:

Fix with stainless steel expansion bolts or self – tapping screws. Determine the spacing based on the sheet size and protect the sheet surface during installation.

Adhesive Fixing:

Use specialized construction adhesive or strong – bond adhesive. Ensure the sheet and base surface are clean and dry. Apply the adhesive as instructed, press firmly, and wait for it to cure.

Edge and Corner Treatment:

Use special stainless steel trim or pressure strips for edges. Cut and fit corners according to the actual angle to ensure a smooth, tight finish.

Maintenance Tips

Daily Cleaning:

Wipe with a soft, damp cloth and water or neutral detergent. For tough stains, use a dedicated cleaner, then dry to prevent watermarks and corrosion.

Regular Maintenance:

Every 3 – 6 months, apply a dedicated maintenance agent or polishing agent, wiping in the same direction to restore shine. Check and fix any installation issues.

Special Stain Treatment:

Remove rust with a rust remover, rinsing and drying afterward. Fix minor scratches with polishing paste by sanding and wiping.

Get Support:

If you require a stainless steel color plate, please let us know your project or job requirements on the Contact Us page.

Fabrication Methods

Plasma Cutting:

For many different thicknesses. Use suitable parameters and then grind edges later.

Laser Cutting:

best suited for small, intricate pieces. Tweak laser settings and deburr

Mechanical Bending:

Work with a bending machine that has suitable molds and radii to prevent sheet defects.

Roll Bending:

Use a roll bending machine with properly designed rolls and adjusted parameters for shaping.

Stamping:

Using dies and stamping machines, perform operations like punching, blanking, drawing, and flanging. Lubricate sheets before stamping and follow operational requirements.